Our L.A.S.T. Manhole Lid and Frame System

Lid Angular Support Technology

The problems with traditional manhole lid systems

Heavy weight means difficult removal and replacement, as well as higher transportation and labour costs. Movement of the frame in the road, caused by braking vehicles, contributes to wrinkling of the road surface.

The L.A.S.T. Difference

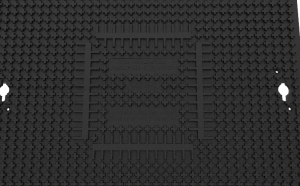

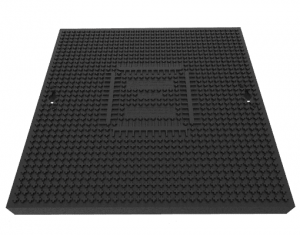

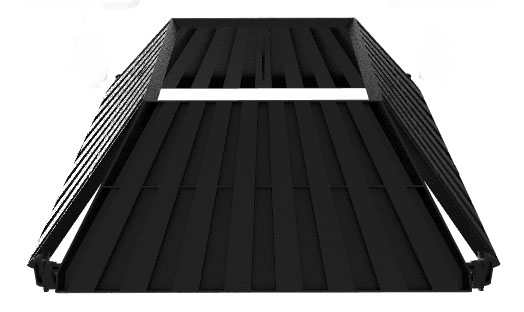

We manufacture our manhole lid system from glass-filled polyester, and our frame from glass-filled nylon. With rotatable struts and a special design on the lid underside, such that the lid can

only be positioned in place once the struts are in the ‘down’ position, our LAST system is the latest innovation in the manhole industry – and a lasting one.

The struts of the frame support the lid mid-span and divert the forces downwards at an angle to the vertical, through the frame base and into the surrounding ground. This allows reduction of the lid weight and lateral forces are dissipated in the ground, well below the road surface. Reduction of span reduces deflection, and the lower manhole lid weight also means lower material, transportation and handling costs.

The struts can be rotated upwards and locked in position, flush with the walls, to allow easy access. The geometry is such that the manhole lid cannot be replaced unless the struts are down, and the struts can be secured to restrict access for safety reasons.

Most of the stresses are compressive rather than tensile, improving product longevity. The extra depth of the frame means that the chamber needs fewer rings.

Lifting keys are also included, and there is an easy-to-use double lock system.

The L.A.S.T. manhole lid only weighs 14Kg yet can take a loading of 25 tonnes – a time-saving, cost-saving solution

To get in touch to discuss a project with us or request more information, send us an email or call on 01204 361547.